PaperSim

PaperSim is the most advanced process simulator for the paper production process in its category. Examples of field of applications are process optimisation, bottleneck analysis and assessment of distinct configurations in revamp studies.

Bottleneck Analysis

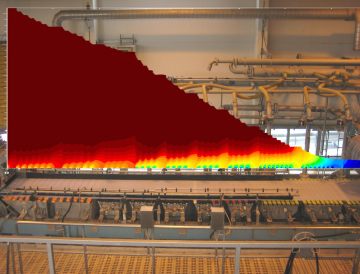

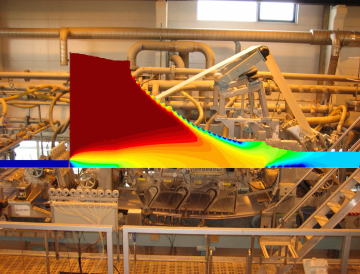

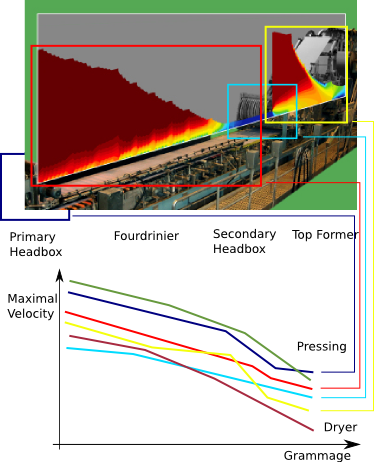

One of the most important applications of PaperSim is in bottleneck analysis (News: Jun 2007), where it is used to determine maximum possible velocity in each part of the paper machine, e.g. headbox, Fourdrinier and top formers, etc. The bottlenecks are the parts of the machine with least maximum velocity. This can easily observed by aggregating the results in a graphic such as below.

PaperSim is then used to assess possible configurations to achieve the desired production levels, e.g. by adding dewatering elements, steam boxes, etc. Below you can download an example report (in abridged format).

» Download an EXAMPLE REPORT of bottleneck analysis.

» Download bottleneck analysis brochure.

Process Optimisation

Several of the process parameters in the paper machine are not optimally set. This is due to the complexity of the process. There are several grades, and frequently each grade need a different set of optimal operating points.

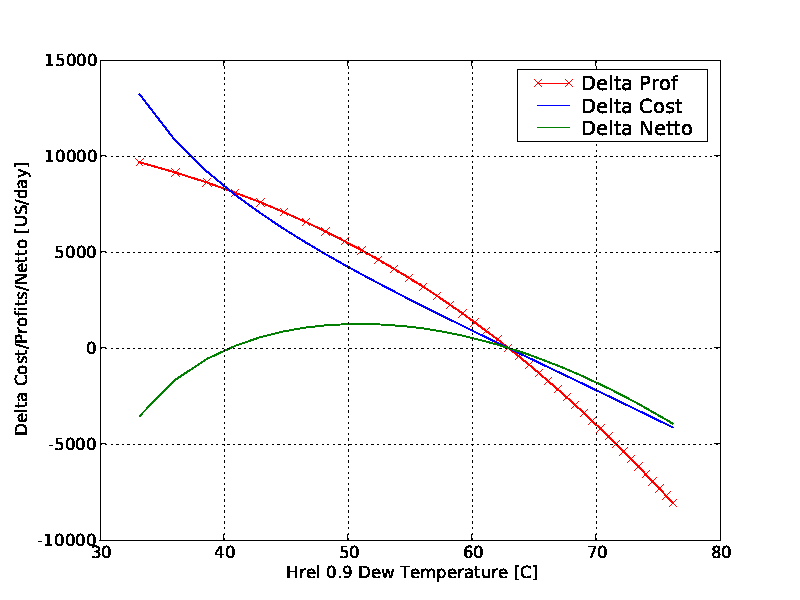

With the help of PaperSim, we perform sensitivity analysis of critical parts of the process, so that optimal conditions for each grade can be estimated. In the figure below, the influence of changing the dew point in the hood of the a pre-dryer can be observed.

A decrease in the hood-air humidity (dew point) lead to improved profitability as the marginal profits more than compensate the increased energy cost with the hood air system (down to 50 ºC). This result depends among other things on the external humidity.

Another common possibility for energy savings is by calculating the optimal vacuum pressure profile along the vacuum section (after the dry-line in the forming section).

» Download an EXAMPLE REPORT report of sensitivity analysis.

» Download process optimisation brochure.

For more information, please, contact:

Vinicius Lobosco, PhD, +46 73 925 8476

or

Klas Samuelsson, PhD, +46 70 668 5515